Project Description

SPECIAL PROJECTS

The continuous further development of our products has enabled us to offer our customers tailor-made systems that can be perfectly adapted to every need. The combination of our linear systems are used in various industries today. A team of technicians is constantly working to find new solutions or to develop customer-specific concepts and ideas.

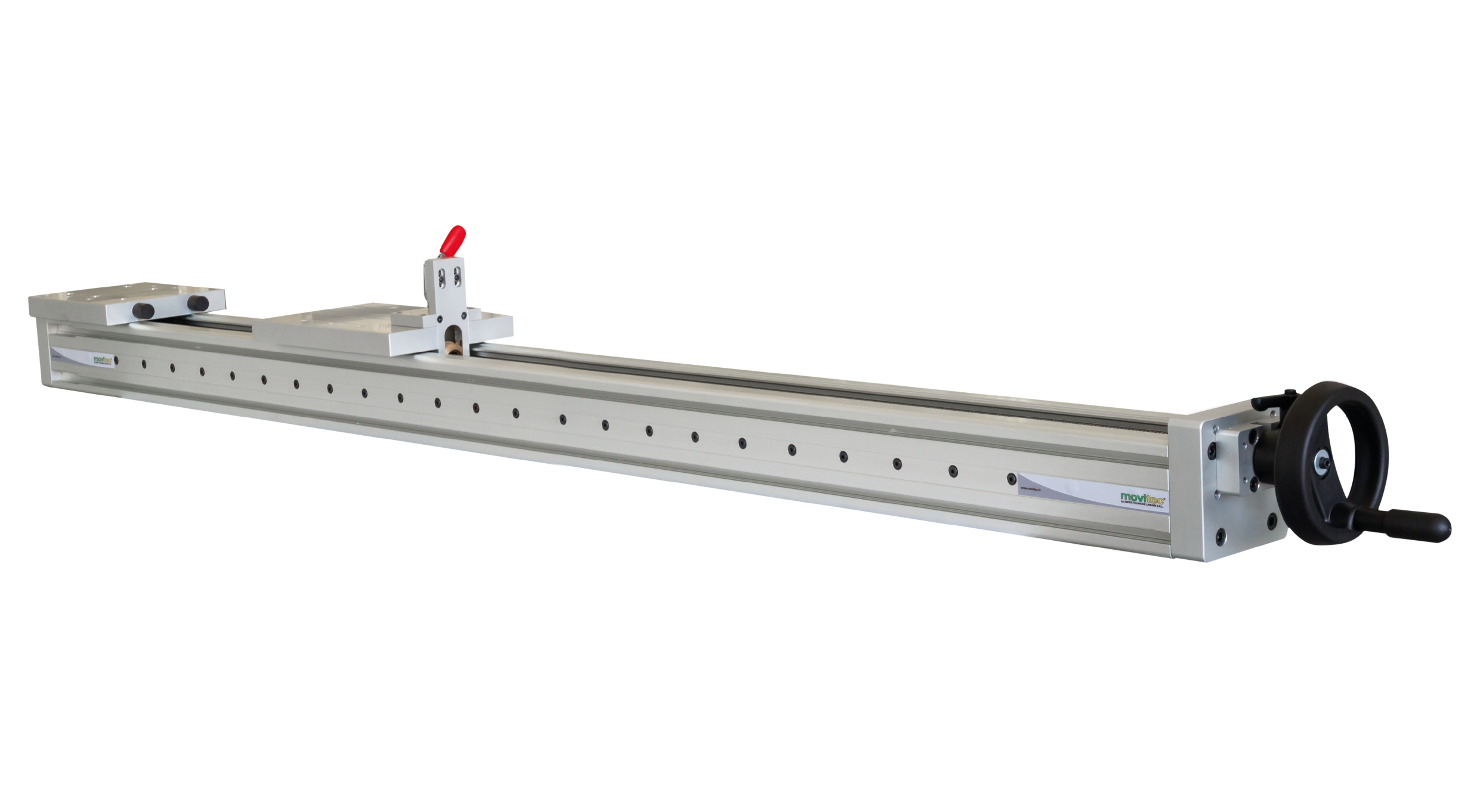

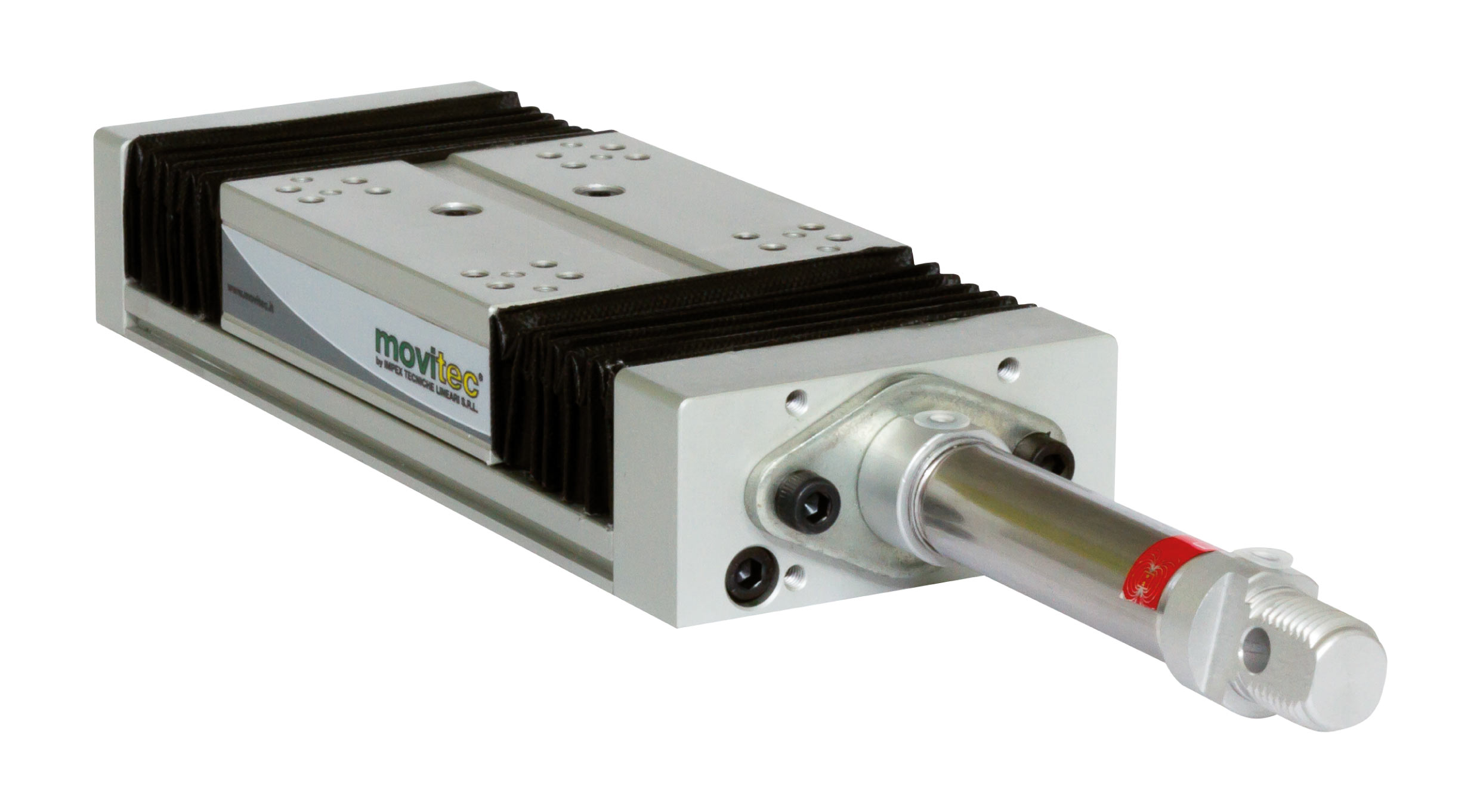

One-Rail Linear Module MCM -pneumatic

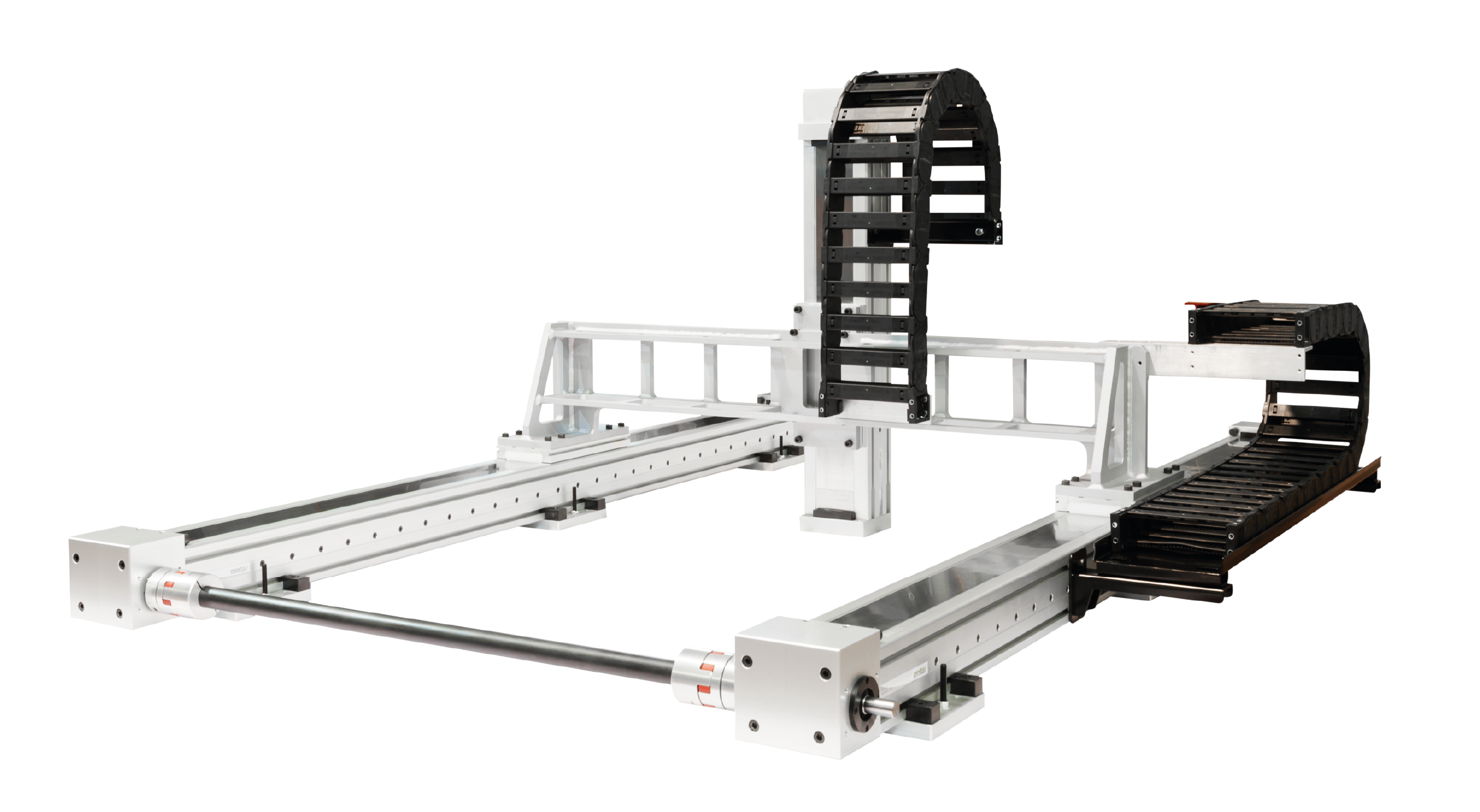

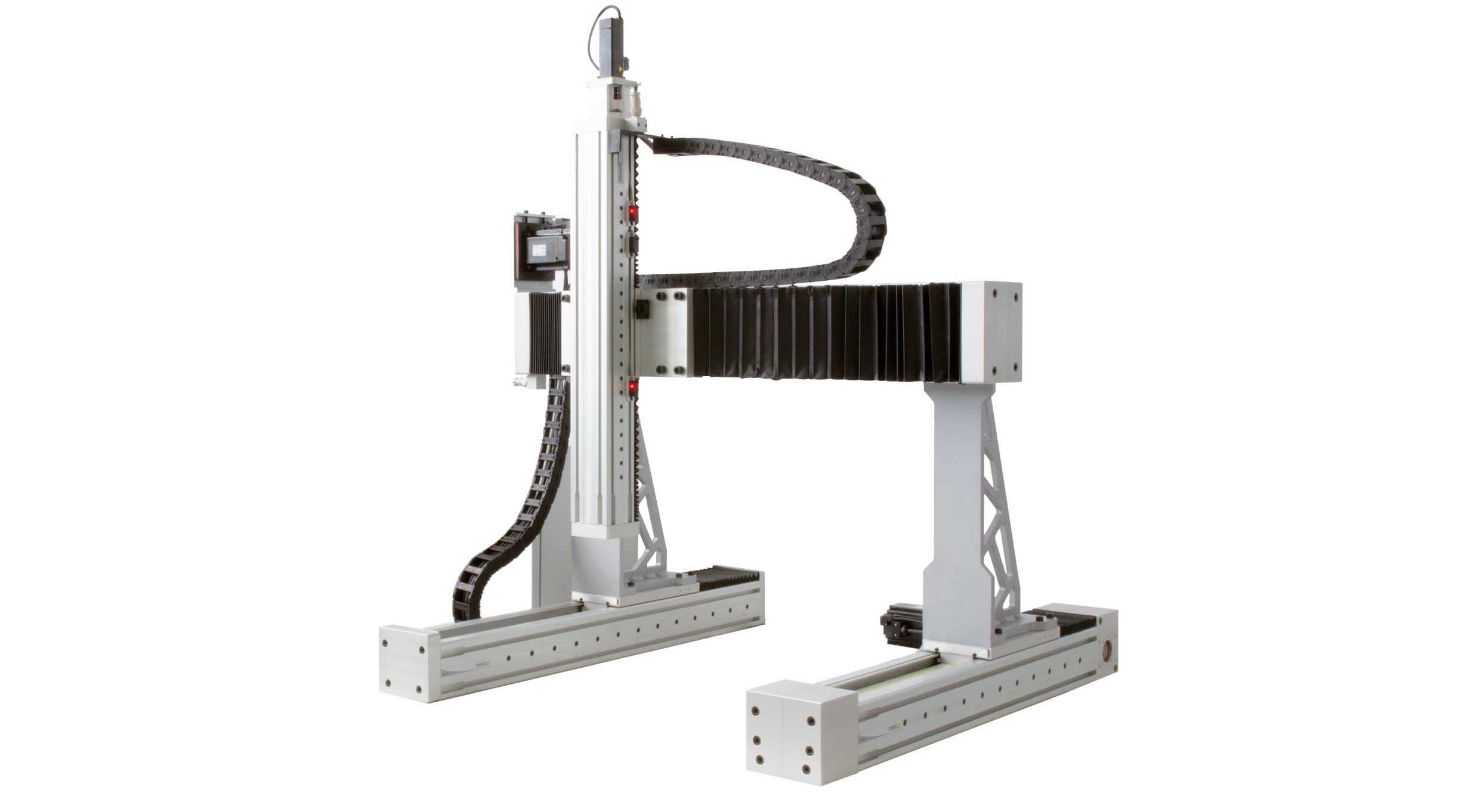

Sincronised X1-X2/Z system for automotive production line

Linear Unit for packaging

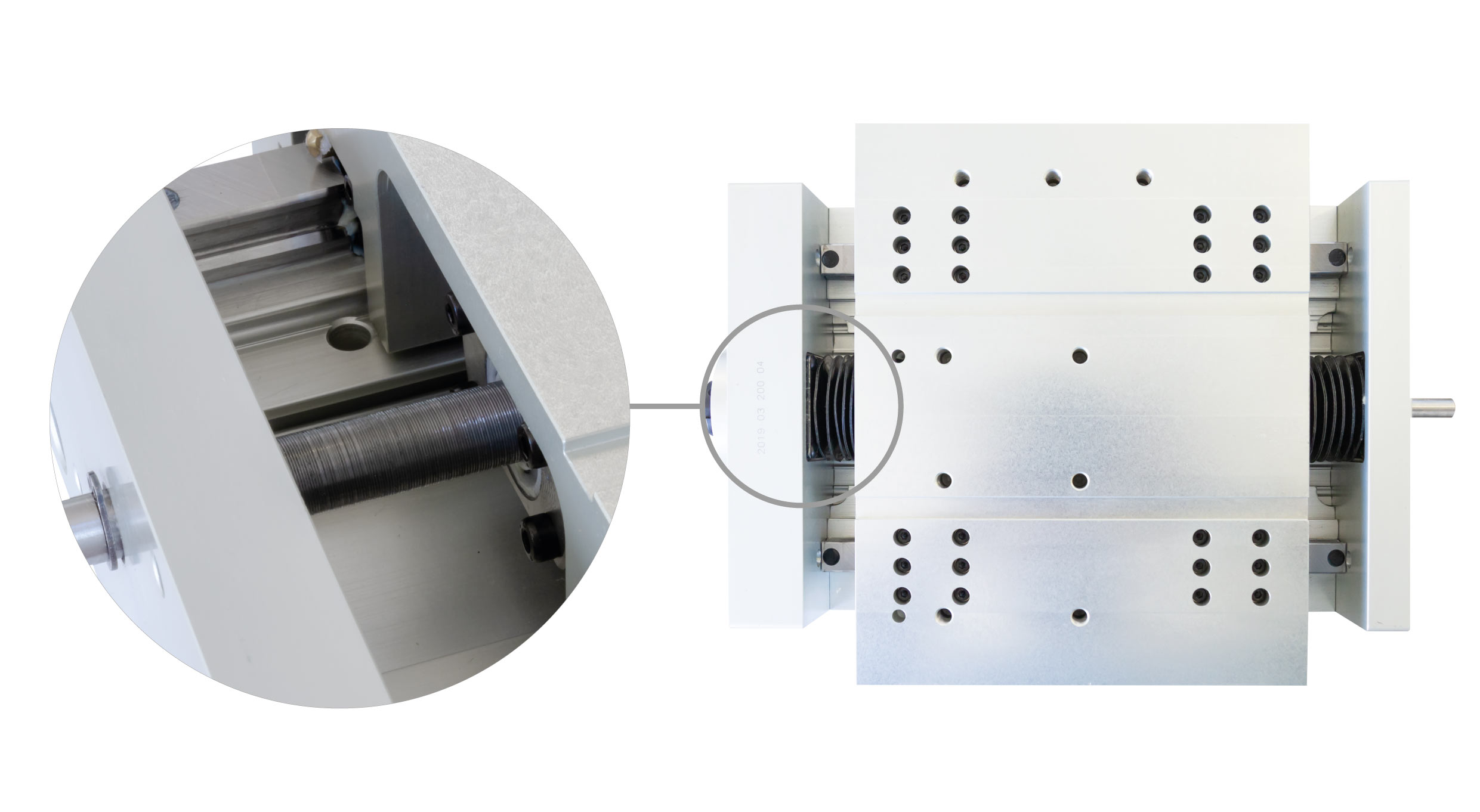

Bi-Rail Linear Module with trapezoidal screw and special blocking

system on bronze nut

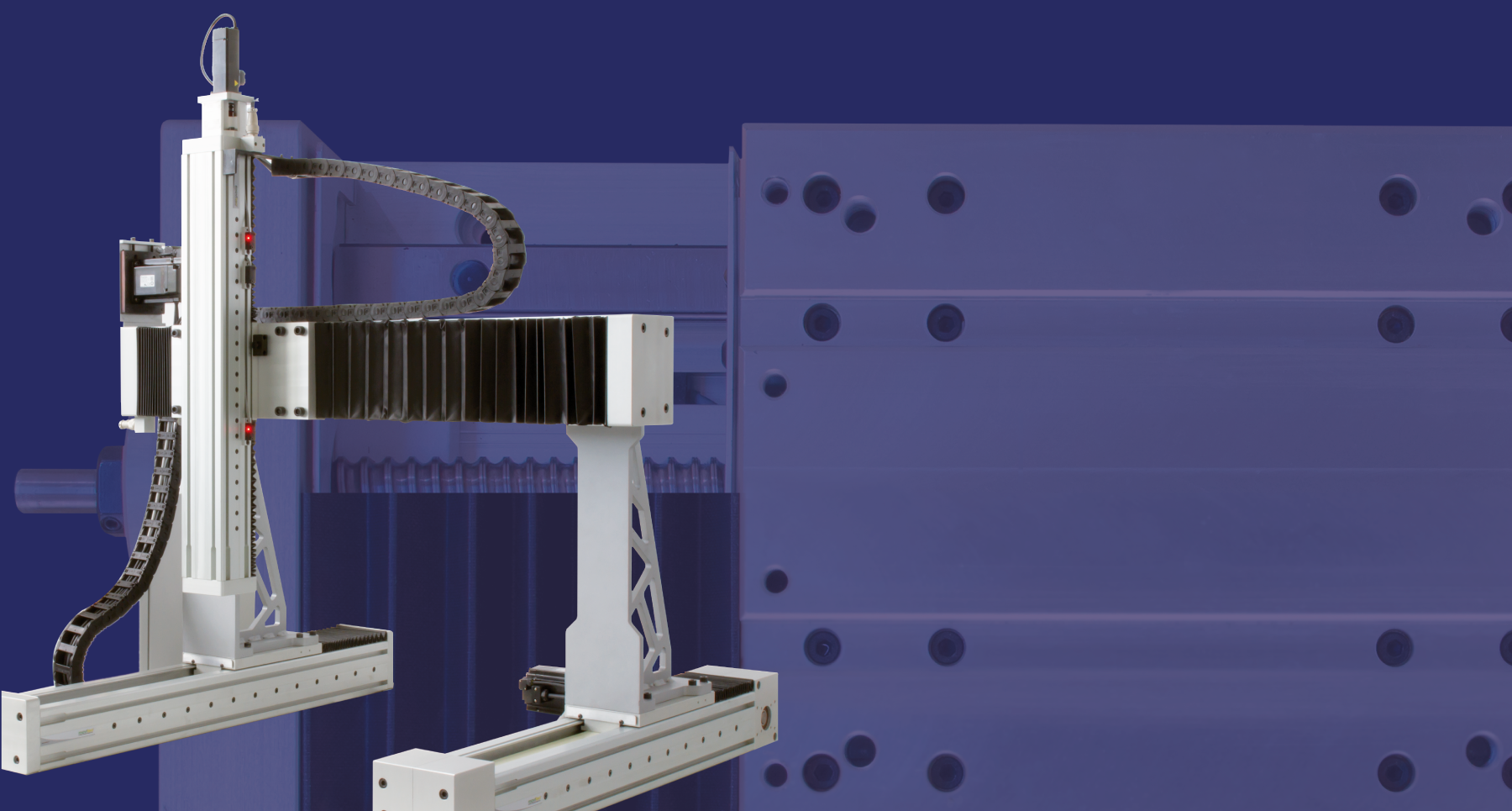

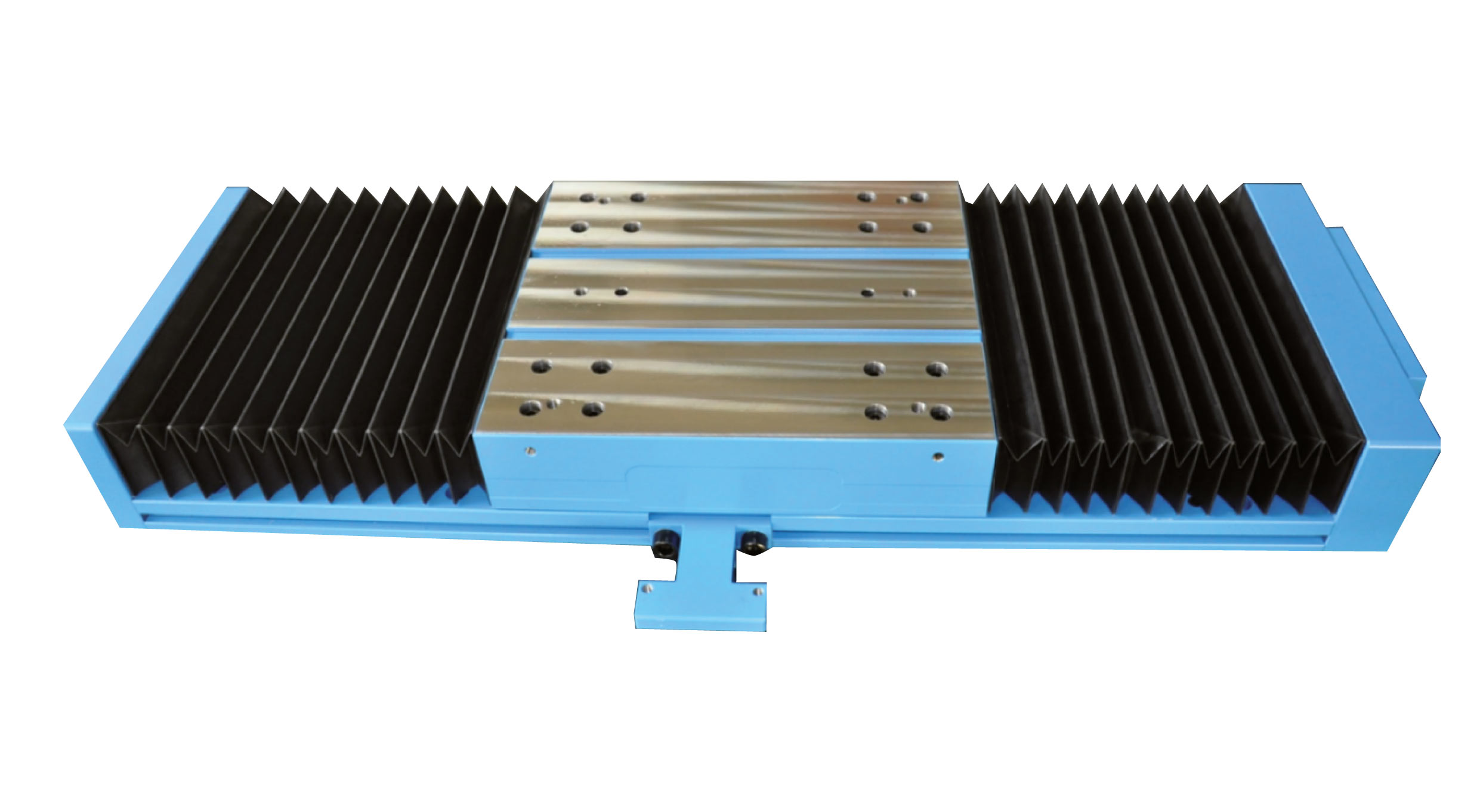

X-Y System with special protection for dusty environments

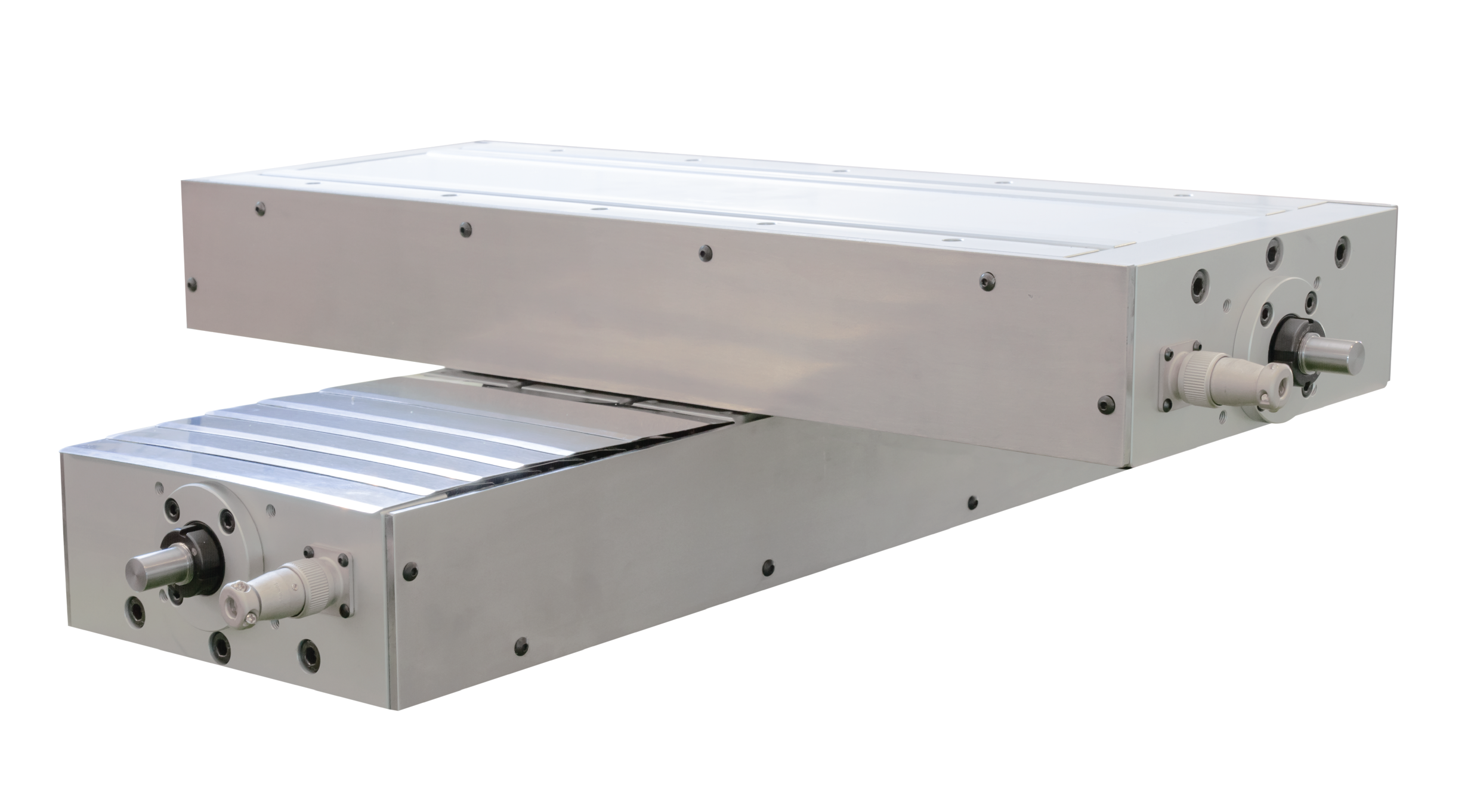

Linear Table with special anticorrosive surface treatment

Linear unit with special long carriage

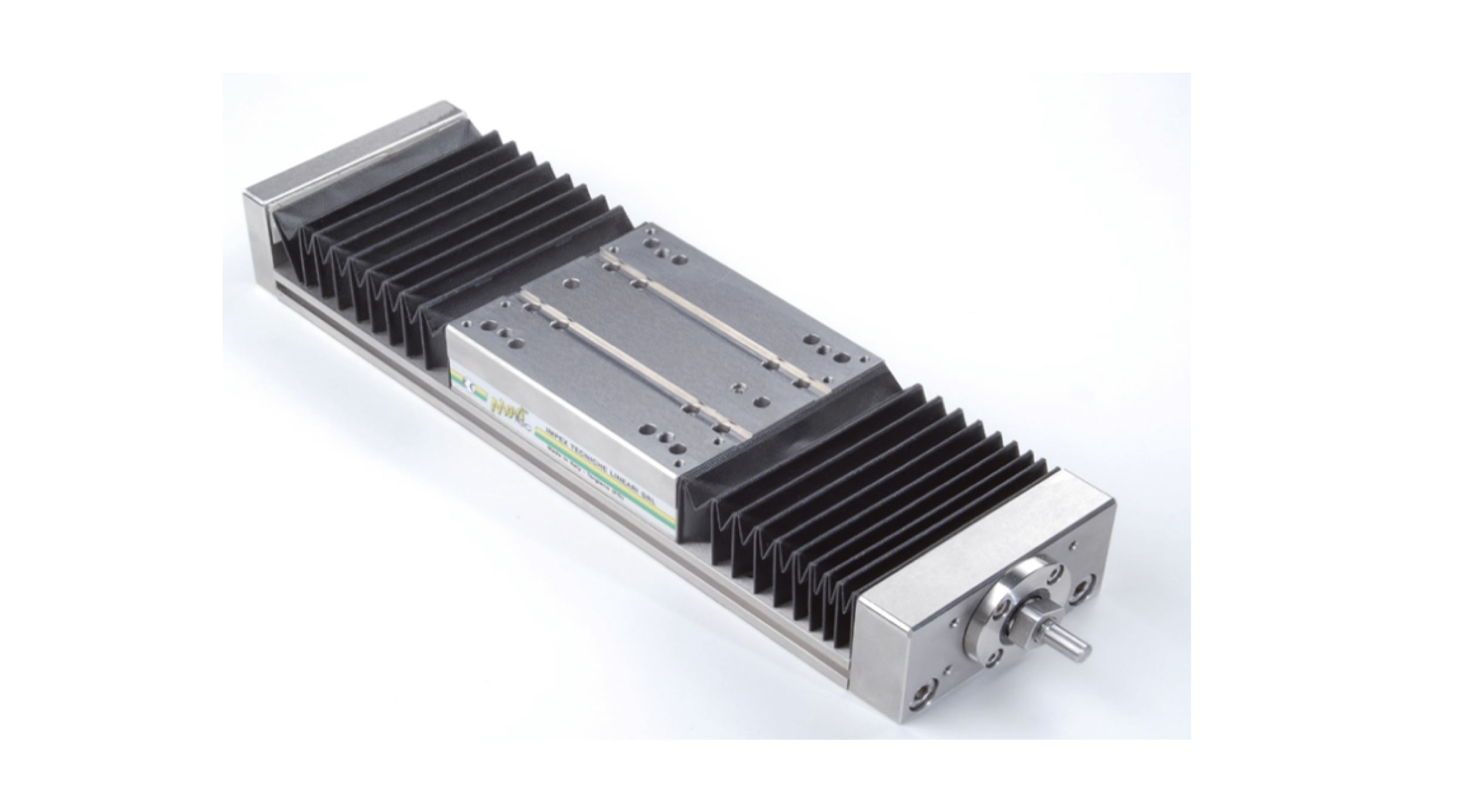

Linear Units CVP060 with and without cover

7-axis drilling and milling machine of profiles

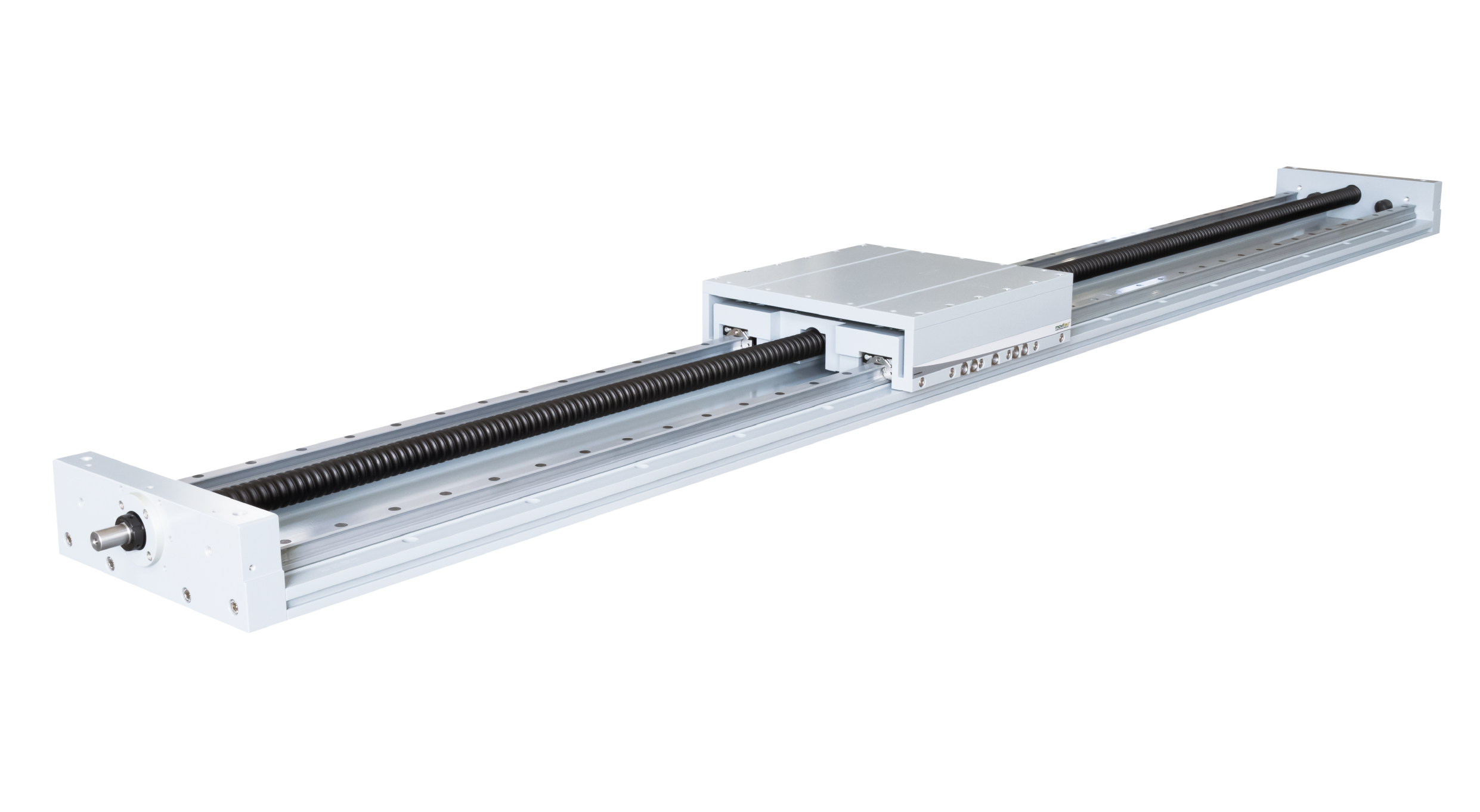

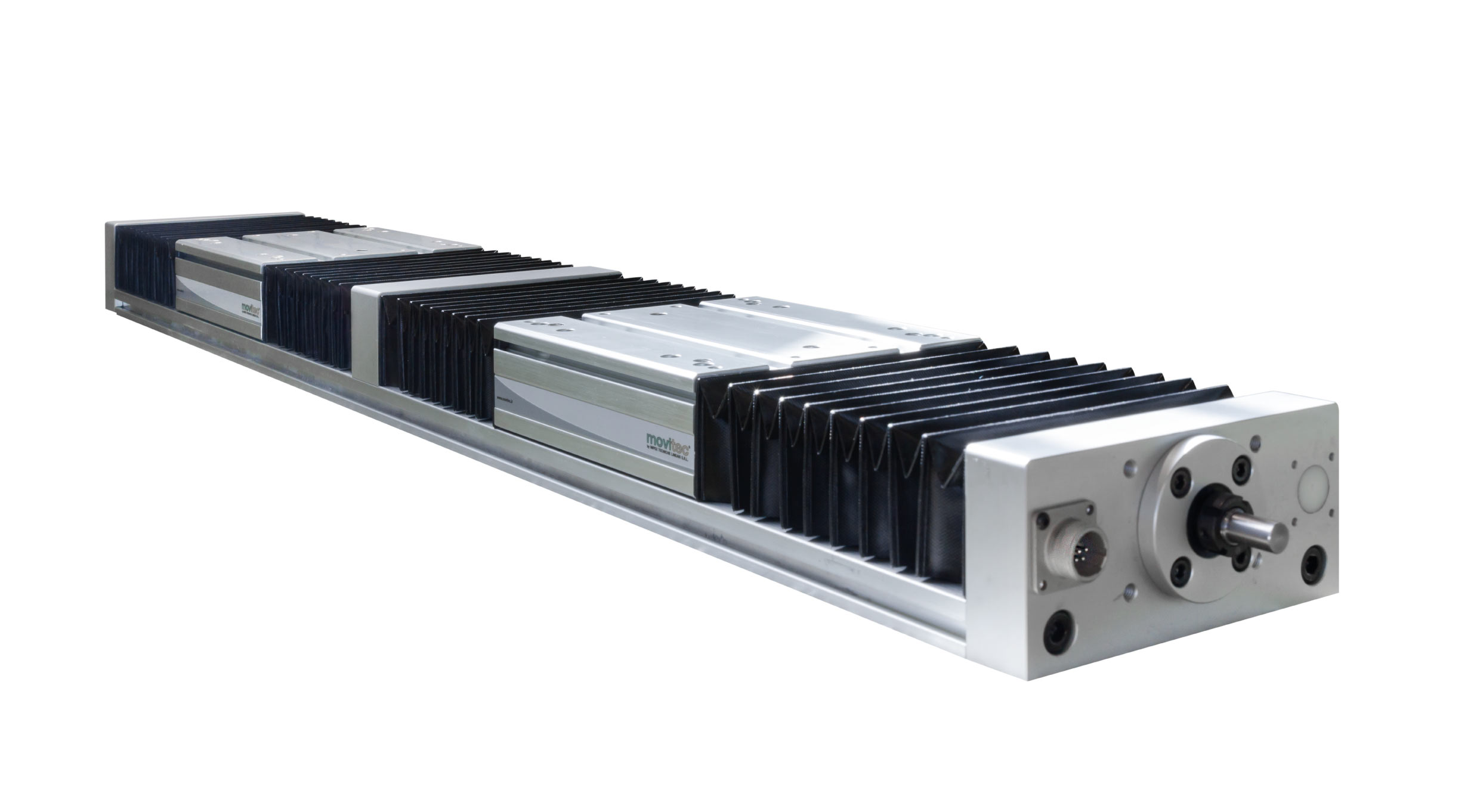

Bi-Rail Linear Module MVP130 with special long carriage and metal strip cover

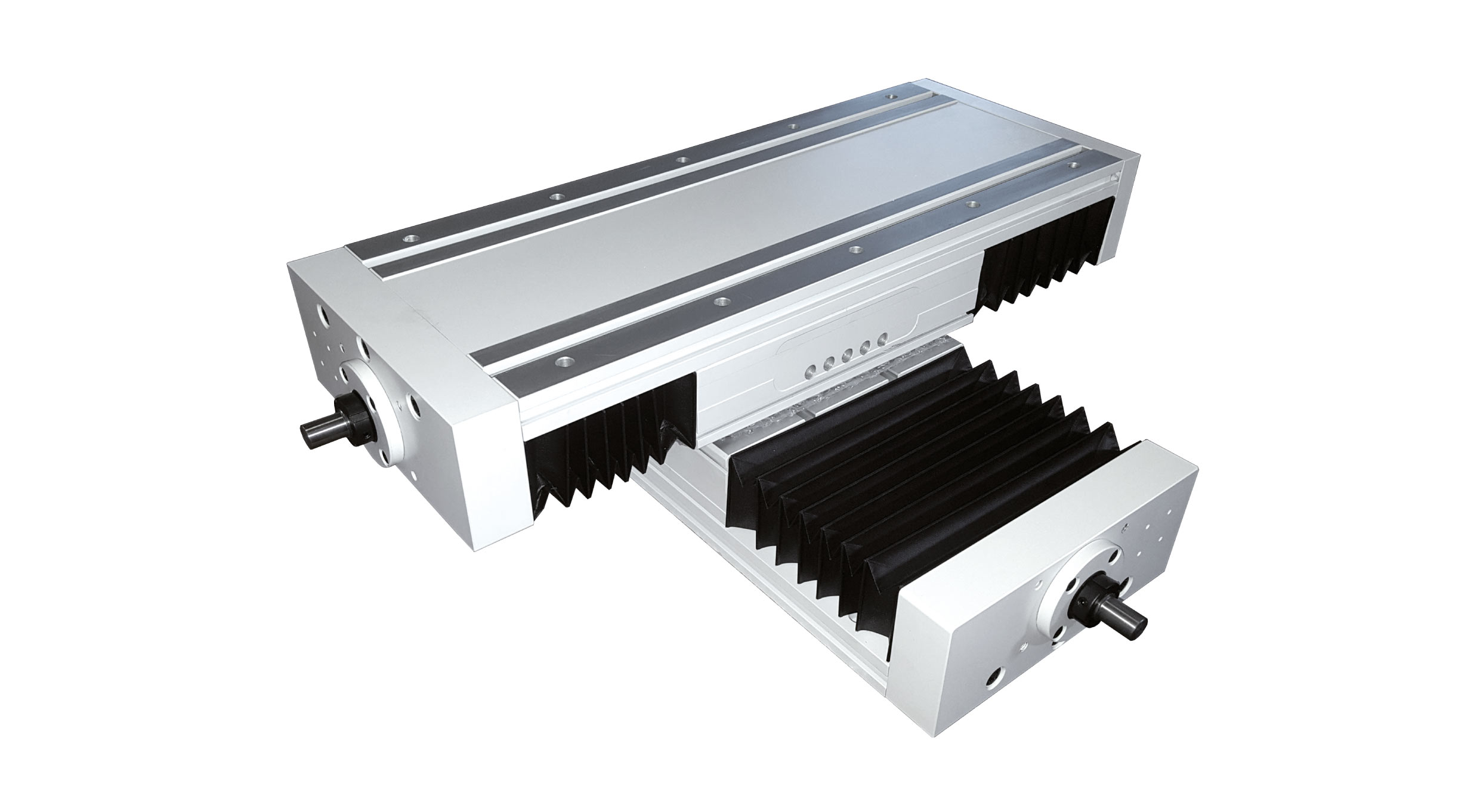

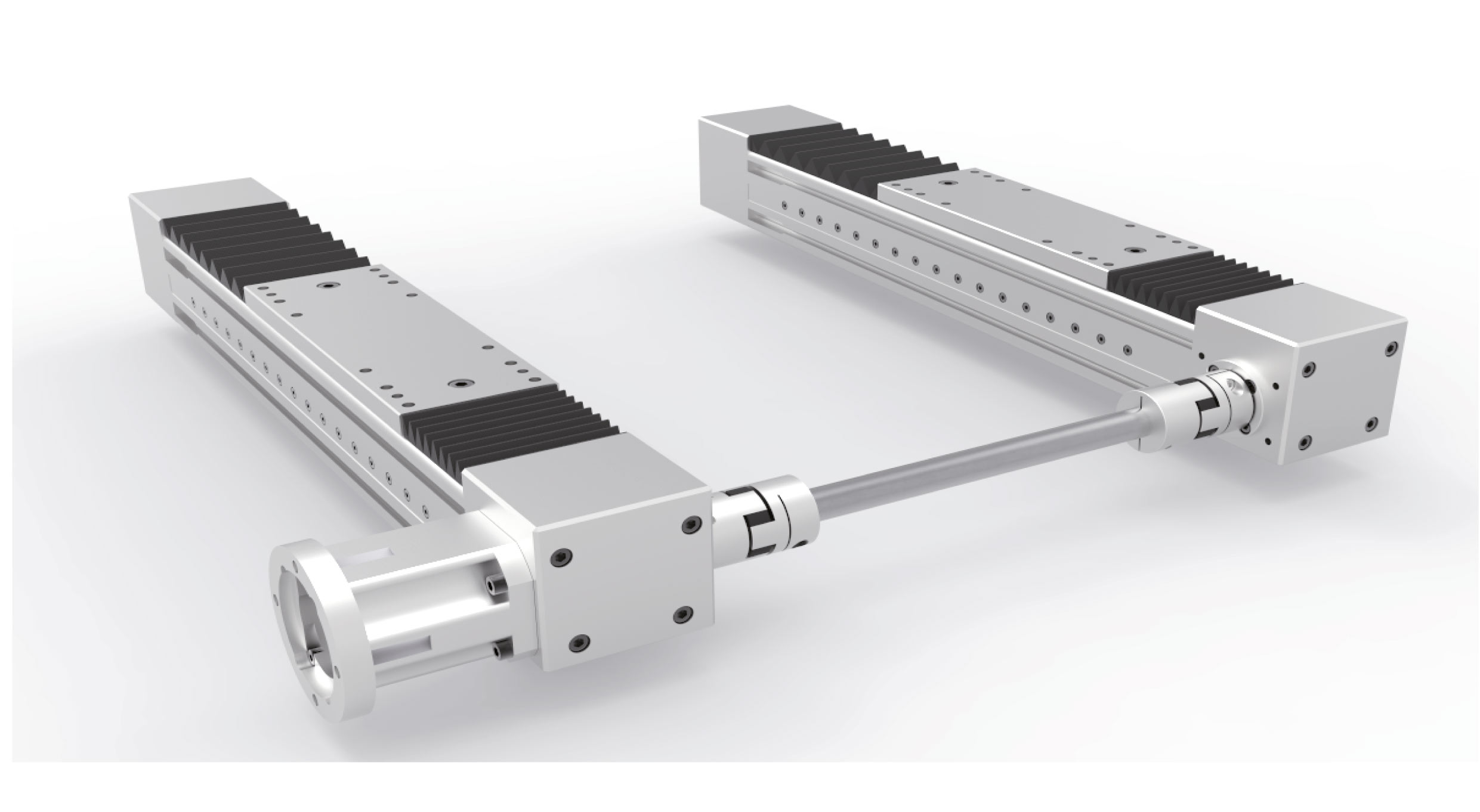

Bi-Rail Linear Module 3 axis system

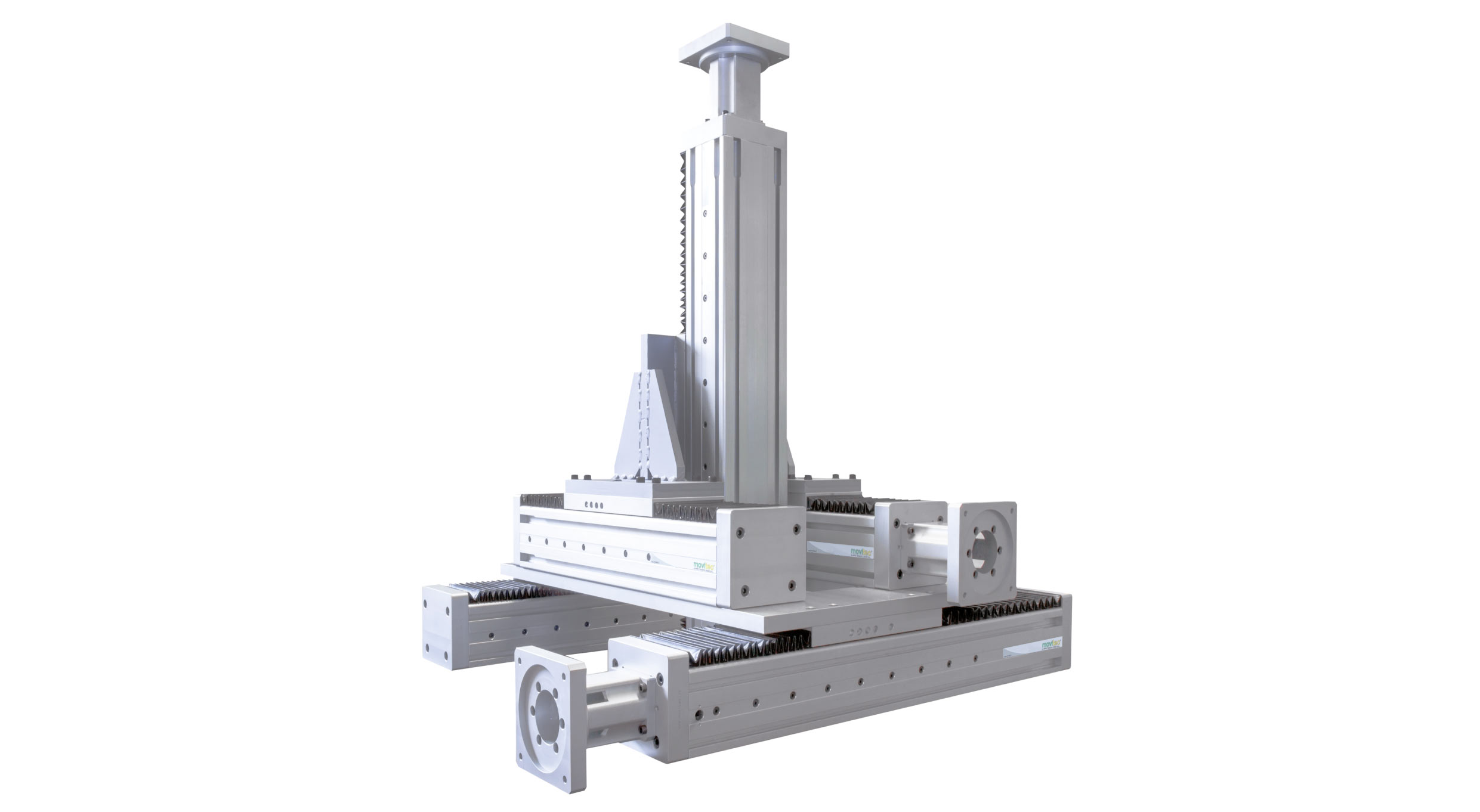

X-Y-Z system for manipulation

Linear Table TVP 250 stoke 30mm with special carriage, satellite roller screw and special protection

Lineartable TVP250 double execution: electromechanic and pneumatic with safety system

Linear Table “Piccola” LVP075 with pneumatic cylinder stroke 30mm

Linear Table in stainless steel with custom painting

TVP100 Linear Table in stainless steel

TPP150 X-Y pneumatic system

Linear Table LVP50 with double carriage and right/left ballscrew,

anodised black colour

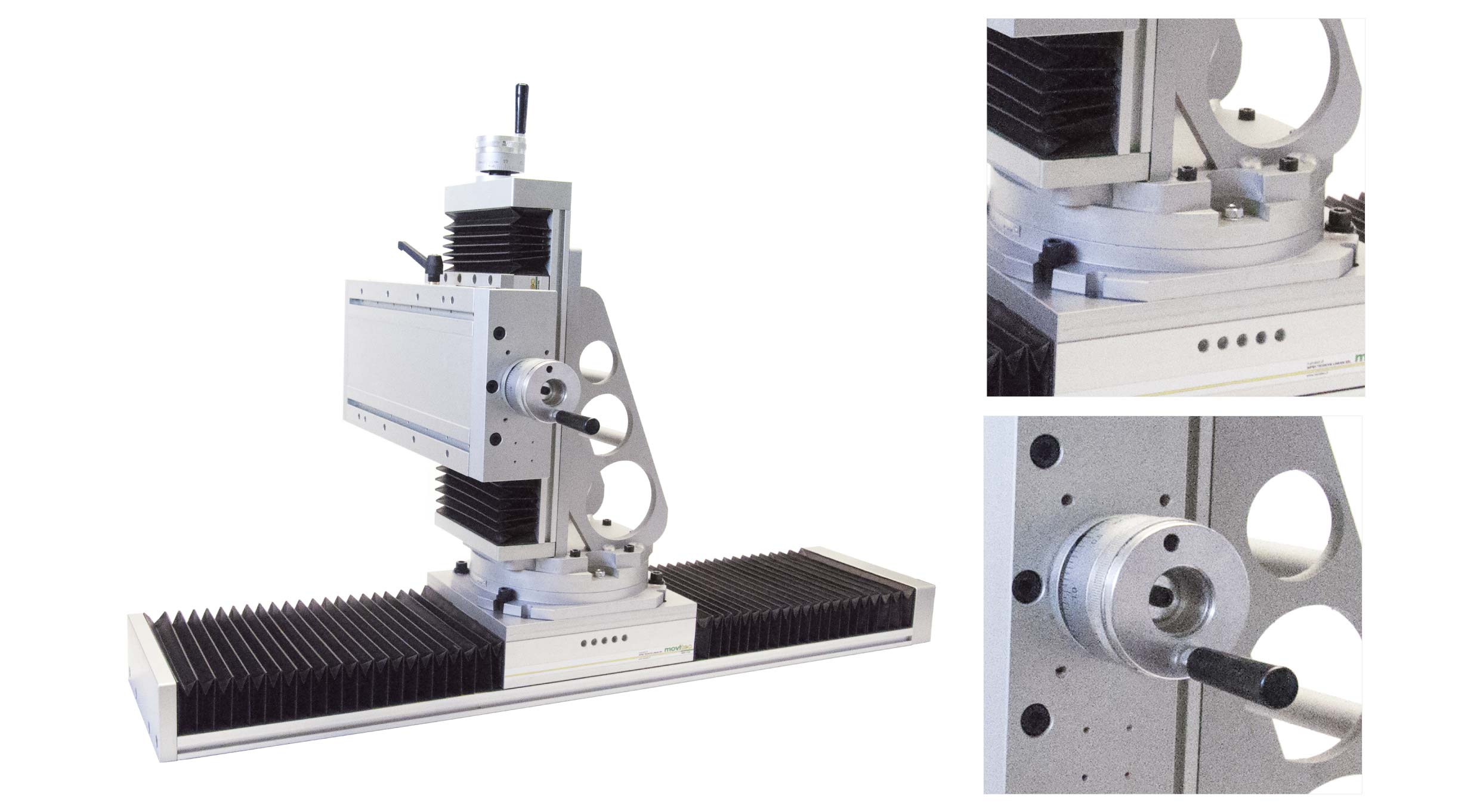

TVP 200 Linear System with rotating axis

MCP70 X-Y-Z system complete with motors, cables and chains

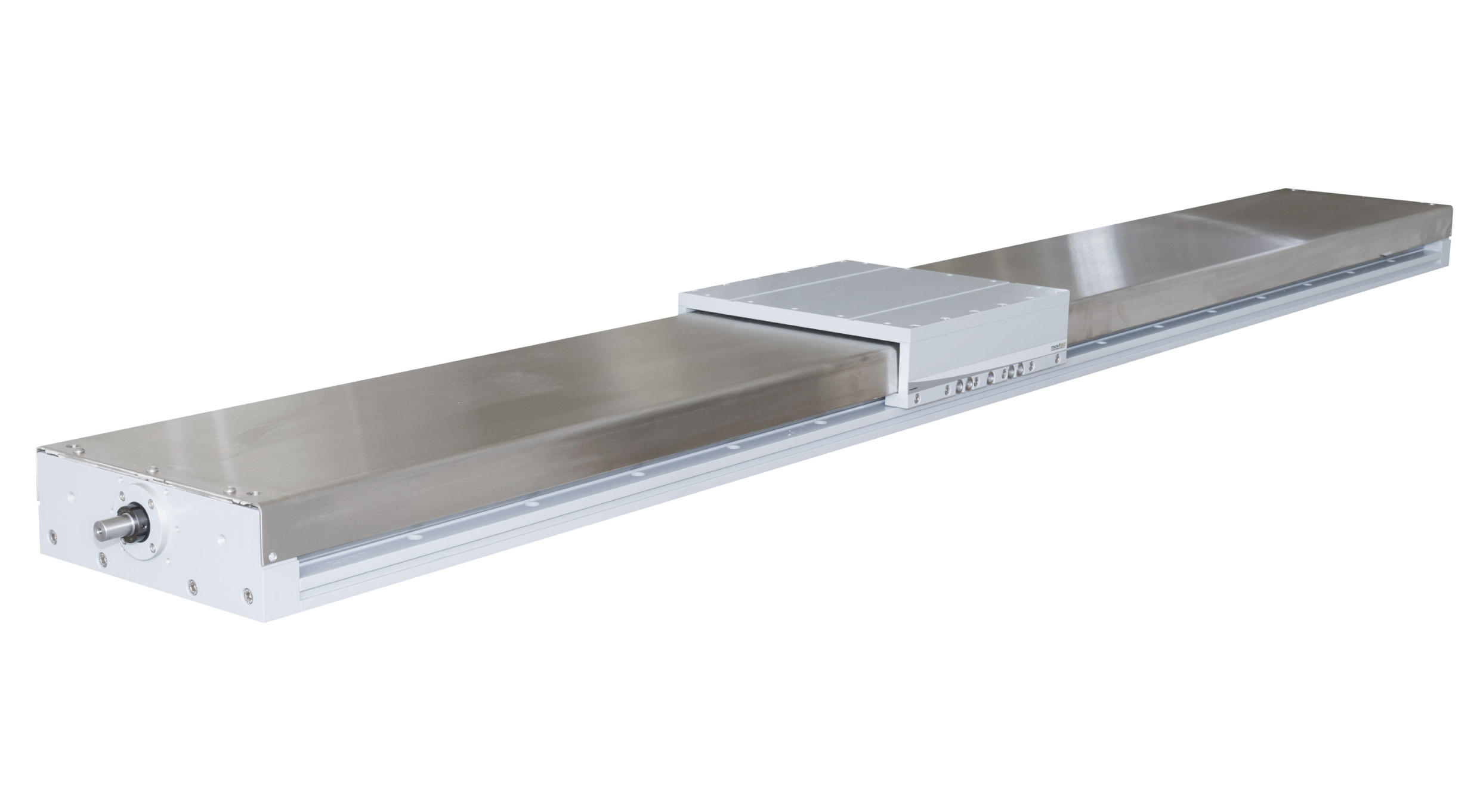

Double Linear Table TVP250

Laser cutting machine

One-Rail Linear Module with metal strip cover

Synchronized system

TVP150 and TVP200 X-Y-Z system with rotating axis

Linear Table in stainless steel with custom painting

TVP300 Linear Table with with metal cover

QUALITY AND FLEXIBILITY – underline our success

Design quality, to guarantee flexibility and modularity of the various products. Production quality with continuous control of machined parts. Top quality material, using precious alloys, regardless whether from full complements or extrusion. Mechanical processing quality, allowing only for very tight tolerances. Assembling quality, measuring and testing of single product. Top selection of all additional components