Project Description

Middex Electronic

MIDDEX broken tool monitoring systems ensure that your products always provide absolute top quality.

Fully functioning tools are essential for quality materials processing. When you choose MIDDEX broken tool-monitoring equipment you are making the best decision to control your processes and ensure the quality of your products. MIDDEX scanning systems have been specifically designed to monitor different sizes of tools. We will select the right system for your project from our standard range, or if required we will design it to meet your specifications or develop a tailor-made solution just for you.

TOOL MONITORING

WK2A – WK2B

– For tools starting from ø 0.3mm

– For checking object, tools or empty space

– Scanning angle 15…270°, left and right

WK5

– For tools starting from ø 0.1mm

– Scan angle from 15 ° to 270 ° – right or left

WK3

– For tools ø 0.1mm

– Scan angle from 0 ° to 270 ° – right or left

PROFIBUS

BKS1S

– Designed to test two tools

– Scan angle from 0 ° to 270 ° – right or left or 360° for empty space

WK10

– Scanning precision 0,01°

– For tools ø 0,3mm (.012”)

MTCE4

– Expansion module for WK2, WK5 and BKS1S to control up to 4 broken tools monitoring systems

PROFINET

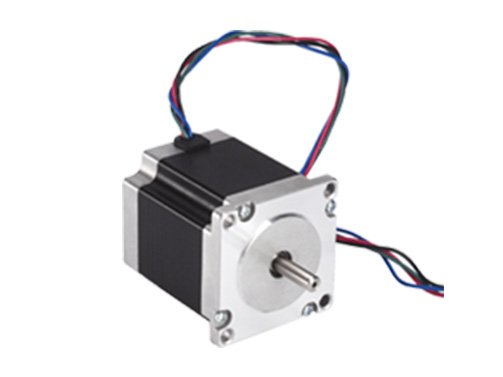

CONTROLLER FOR STEPPER MOTOR

POSITION CONTROLLER

3-PHASE CONTROLLER

2-PHASE CONTROLLER

5-PHASE CONTROLLER

CONTROLLER FOR DC MOTOR

POSITION CONTROLLER

ANALOG INTERFACE

STEPPER MOTORS

STANDARD VERSIONS

SPECIAL VERSIONS / CUSTOMIZED

QUALITY AND FLEXIBILITY – underline our success

Design quality, to guarantee flexibility and modularity of the various products. Production quality with continuous control of machined parts. Top quality material, using precious alloys, regardless whether from full complements or extrusion. Mechanical processing quality, allowing only for very tight tolerances. Assembling quality, measuring and testing of single product. Top selection of all additional components